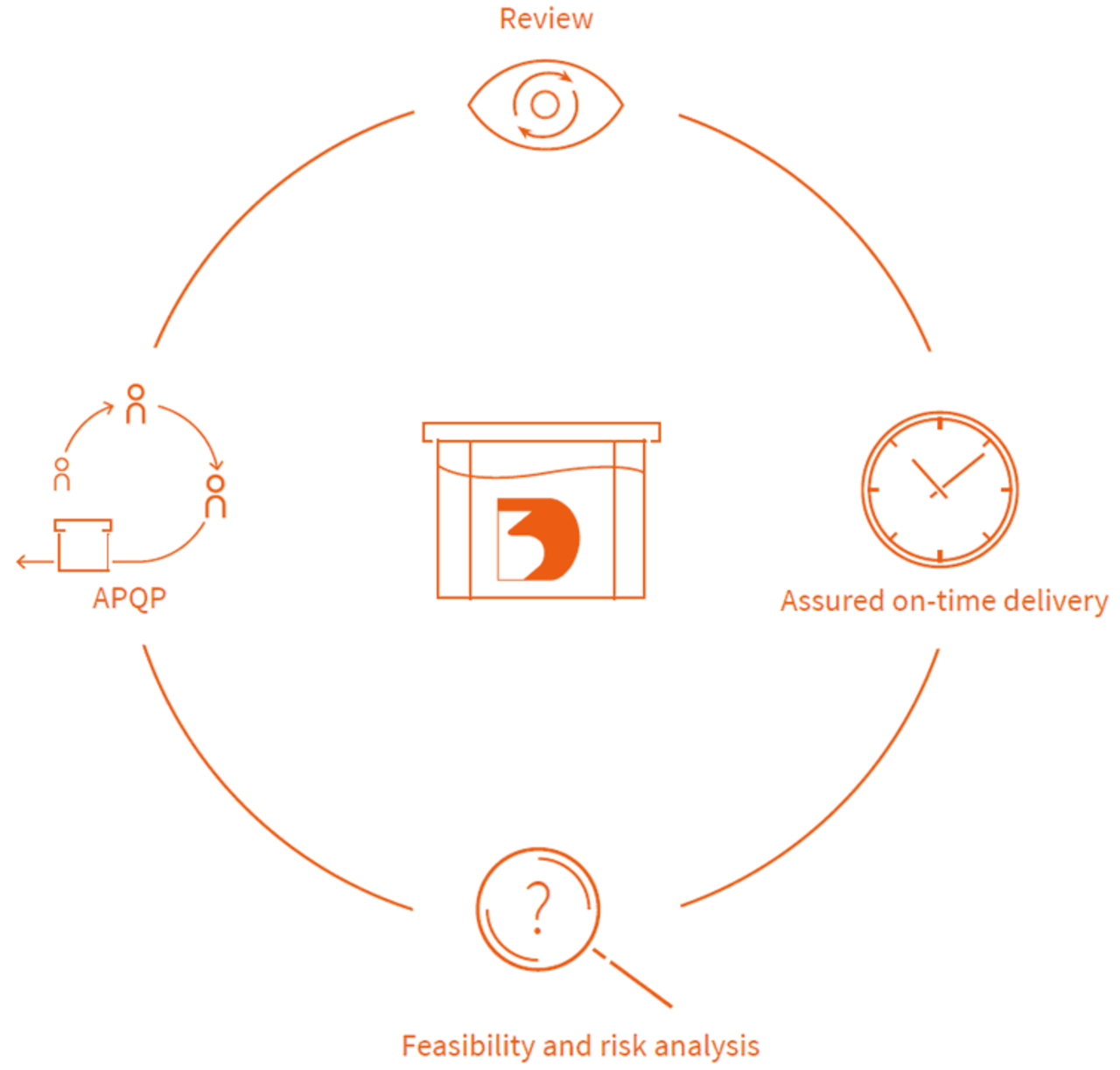

Good planning is expressed by the satisfaction of our customers.

You can count on us. We use modern project planning tools to ensure that the products you receive from us are not only perfect, but also arrive on-schedule. It always starts with a reliable and realistic plan for the production and implementation of your project. And: Your named point of contact is there for you, all the way from development to volume production readiness.